Storing Out of the Box: Innovative Storage Solutions

Changing e-commerce and customer needs have put pressure on fulfillment centers to increase productivity with the same warehouse space. Out of demand comes innovation. The innovative storage solutions of SpeedCell can be custom designed to fit any kind of warehouse. These SpeedCell customers worked with our design team to create custom storage solutions not found anywhere else.

Less space, more racks

This customer’s current solution uses long, corrugated bins to store molds/parts. They had to pull the deep bins out fully to pick orders on both the floor level and 50 feet up. For the higher shelf levels, they used a vertical lift to reach the bins.

They needed a better solution to condense their current storage and add more space. Our dealer asked us to design a solution for them.

The first test SpeedCell bay eliminated 7 beam levels and added an additional 38 locations at the floor level. This solution also solves the issue of pulling the deep bins out. Now they’re able to simply reach into the cells and pull out the parts. This saves considerably on picking time and makes picking more ergonomic as well as safer on the high levels.

This solution not only adds additional SKU locations, but the customer is able to free up storage space and reuse the displaced beams without adding to their storage footprint.

Lightweight GOH solution

This installation was for Capacity LLC, a 3PL who offers product and e-commerce fulfillment. For one of their customers, a major cosmetics brand, they needed a way to move empty cardboard shells from packing to shipping, as well as store and transport stacks of empty shells.

They decided on a GOH (Garment on Hanger) solution. The system offered a lightweight, mobile solution that was customizable to their product size. They researched hanging carts/cages, but with SpeedCell, they could scrap the heavy, expensive cages and instead use suspended fabric columns.

One concern with a monorail on a cylindrical track is the rotation where the trolley bar meets the rail, and where the column connects to the trolley. SpeedCell engineered a custom, inexpensive stabilizing system which eliminated sway at the column connection point and significantly reduced sway at the rail. Capacity LLC put the system through intensive testing and found that even fast momentum around corners did not dislodge the trolley from the track.

Not only did this monorail solution save on the storage footprint, but the entire 1,500 foot long system was a fraction of the cost when compared to a conveyor. And, unlike with a conveyor, both empty and filled shells are able to be stored within the SpeedCell columns, saving time on labor and reducing required storage space.

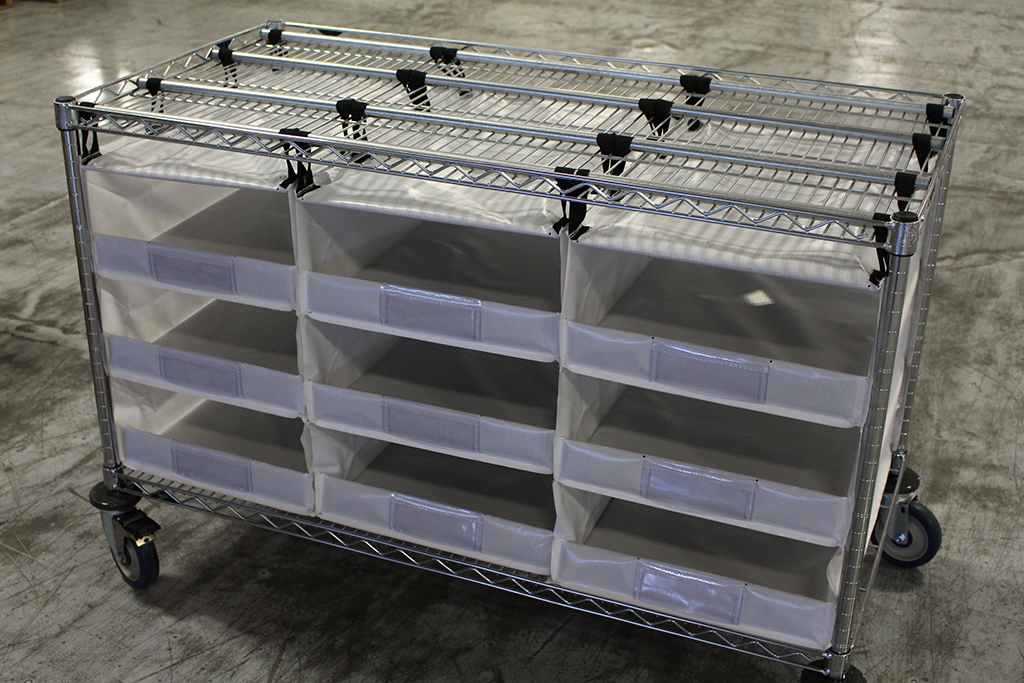

Driving solution for medical supplies

This customer had need of a custom cart to store medical supplies. They wanted flexible, mobile storage underneath desks and surgical tables.

SpeedCell designed a 36” tall custom cart to fit their exact size requirements, improving their storage capabilities with a sturdy cart able to be clean and sanitized for medical use. These carts will be used in 16 medical centers across the United States.

These designs demonstrate how SpeedCell’s storage solutions can be designed to fit any kind of warehouse or demand. We specialize in custom designed storage solutions. Is your warehouse looking for an innovative solution to increase storage density and lower cost simultaneously? Challenge us!